Industry news

How to test the quality of compostable bags?

Testing the quality of compostable bags involves evaluating their performance and suitability for composting processes. Here are some steps

you can take to test the quality of compostable bags:

1. **Certification and Standards**: Check if the compostable bags are certified by reputable organizations such as the Biodegradable Products

Institute (BPI) or the European compost certificates logo. These certifications indicate that the bags meet specific compostability standards.

2. **Material Analysis**: Understand the composition of the compostable bags. They are typically made from materials like PLA (polylactic acid),

PBAT (polybutyrate adipate terephthalate), or a combination of these. Analyze the material properties to ensure they are suitable for composting.

3. **Degradation Testing**: Conduct degradation tests under controlled composting conditions. Place the bags in a composting environment

(industrial or home composting), monitor their degradation over time, and assess the rate of decomposition. Measure factors like weight loss,

structural integrity, and appearance.

4. **Biodegradation Assessment**: Perform tests to determine the rate at which the bags break down into smaller fragments. This can involve

visual observations and microscopic analysis to assess the degree of degradation.

5. **Chemical Analysis**: Test the compost produced from the compostable bags to ensure that no harmful chemicals or residues are present.

This can involve analyzing the compost for heavy metals, toxic compounds, and other contaminants.

6. **Mechanical Strength**: Assess the strength and durability of the compostable bags under different conditions, such as load-bearing

capacity, tensile strength, and tear resistance. This ensures the bags can hold waste without breaking during use.

7. **Disintegration Testing**: Evaluate the bags' ability to disintegrate into small pieces within a specified timeframe. Disintegration tests

involve measuring the time it takes for the bags to break down into fragments under composting conditions.

8. **Temperature and Humidity**: Composting conditions can vary based on temperature and humidity levels. Test the bags' performance

under different temperature and moisture conditions to ensure they break down effectively in various composting environments.

9. **Microbial Activity**: Study the interaction between the compostable bags and the microbial activity in the compost. Microbial activity

plays a crucial role in breaking down the bags, so it's important to ensure a healthy microbial population in the compost.

10. **Comparison with Control**: Compare the degradation of compostable bags with a control material (such as traditional plastic) under

similar composting conditions. This helps demonstrate the superiority of compostable bags in terms of environmental impact.

11. **Field Trials**: Conduct field trials in real composting facilities or composting bins to evaluate the bags' performance in real-world

conditions. Monitor their degradation and interactions with other compostable materials.

12. **Consumer Feedback**: Obtain feedback from consumers who have used the compostable bags for waste disposal. This can provide

insights into their practical usability and performance.

Remember that the testing methods may vary depending on the specific type of compostable bags and the intended application. It's

important to follow established standards and guidelines for compostability testing to ensure accurate and reliable results.

Below are the recommended china high quality compostable bag manufacturer:

china compostable garbage bag manufacturer

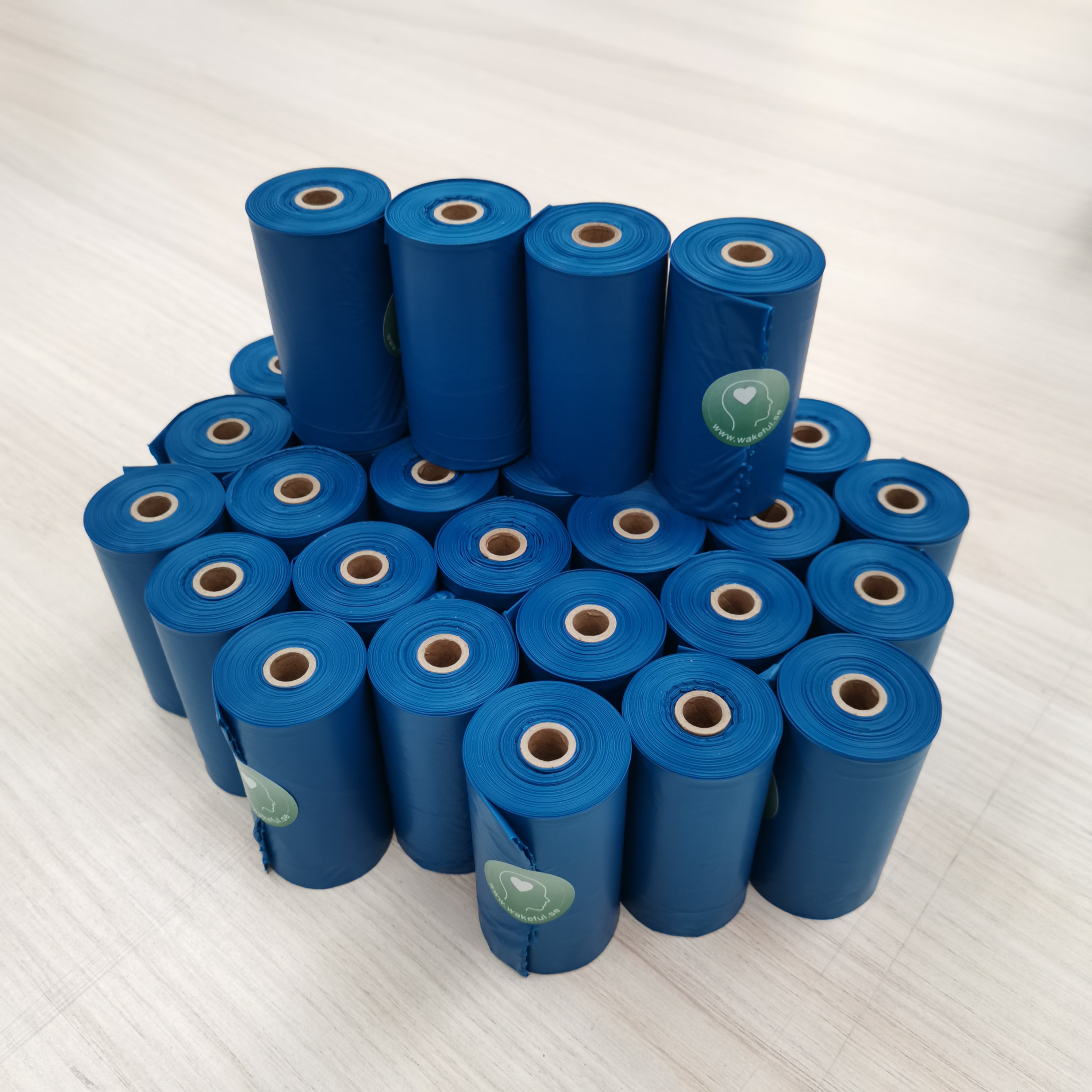

biodegradable dog poop bag manufacturer

china biodegradable t-shirt bag manufacturer