Industry news

What causes the quality of compostable bags to decline?

The decline in the quality of compostable bags can be attributed to several reasons:

1. **Inadequate Material Quality**: Substandard materials used in manufacturing compostable bags can lead to lower durability and faster degradation. Compostable bags usually use PBAT as the basic raw material, which accounts for about 70%-80%, and then add PLA and corn starch. Therefore, the quality of PBAT used by the manufacturer determines the quality of compostable bags. Good quality PBAT can make the selt life of the compostable bag up to one year and even more, but poor quality PBAT can cause the bag to lose its original performance and become as fragile as paper in just a few months.

2. **Poor Manufacturing Processes**: Improper handling during the production phase, such as incorrect temperature control or insufficient mixing of components, can result in bags that degrade prematurely or lack strength. Compostable bags are usually made of PBAT as the basic raw material and then modified by adding PLA and corn starch and then remade into granules to blow film then make the bags. Therefore, good modification technology by manufacturers is also very critical. Good modification technology can give full play to the original properties of raw materials, such as modification formula, usage ratio of various raw materials, modification temperature control, etc., and at the same time, when blowing film Temperature control also directly affects the quality of the film and thus the quality of the bag.

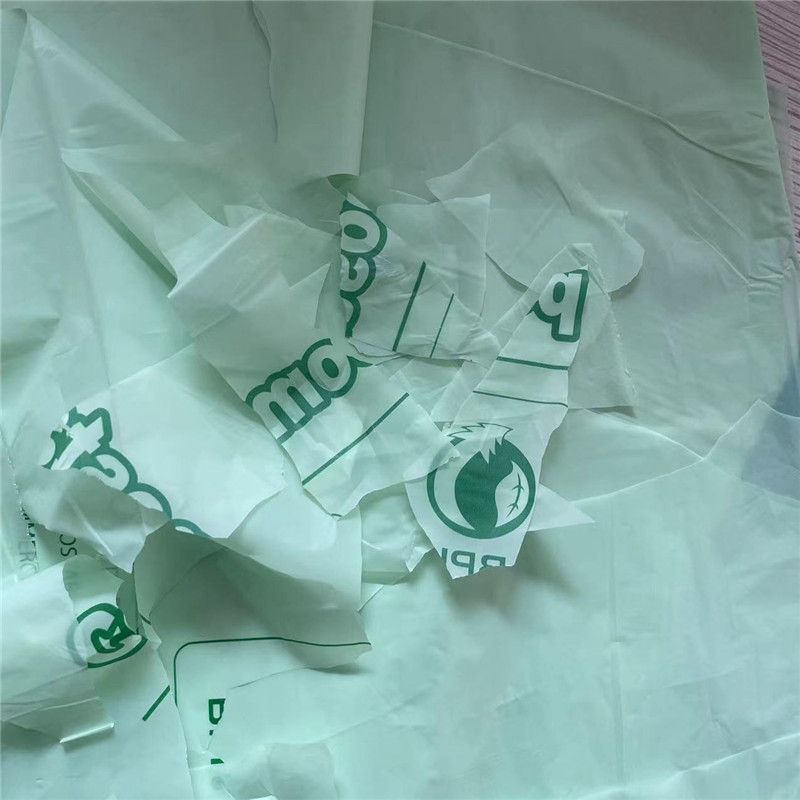

3. **Add recycled materials**: In order to save costs, manufacturers sometimes turn low-quality compostable bags that have been stored for a long time into pellets and reuse them as recycled raw materials. If too much recycled material is added to the bag, the original performance of the bag will be lost in just a few months.

4. **Storage Conditions**: Improper storage conditions, such as exposure to moisture, sunlight, or extreme temperatures, can accelerate the degradation of compostable bags before they are even used. The correct storage conditions for compostable bags are: low temperature, dry, dark, and sealed conditions. If cornstarch is added to the bag, since the bag made of cornstarch has the fragrance of food, it needs to be prevented from being bitten by mice. When compostable bags leave the factory, manufacturers need to seal the inside of the carton to prevent high temperature and humidity from affecting the shelf life of the bag during sea transportation.

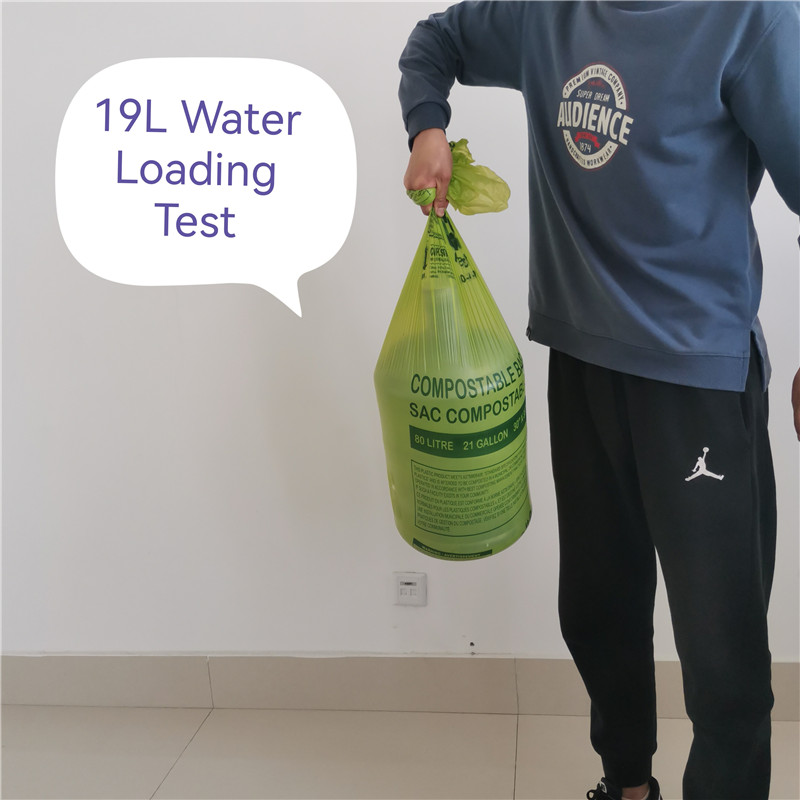

5. **Keep for long time**: Under normal conditions, the shelf life of the bag is one year. Due to the degradability of the bag, the raw materials of the bag will slowly degrade over time, causing the bag to lose its original performance. If the bag is left for too long, it will like paper Easily torn.

5. **Procurement advice**: It is recommended to reasonably plan the sales cycle and purchase in small and multiple batches to ensure that each batch of goods has a long shelf life and sufficient sales time to avoid long inventory time affecting the quality of bags and causing customer complaints.